The catch is that almost all of these drawings of barbell racks are designed for the use of welding, and its use at home is very problematic.

But, a bench press rack can also be assembled from wooden boards and timber purchased at the nearest construction market. You can take a tape measure with you and, having marked the cutting areas, ask for the timber to be cut right at the place of purchase. Usually this service is free on the construction market.

After reading this article, you can make your own barbell press rack right in your room.

Main types and features of a bench press machine

There are different types of bench press:

- Horizontal - can be folding or regular. Mainly refers to stationary types of sports equipment. Often there are racks for projectiles, as well as various attachments and clamps. Usually such a simulator has little functionality, but with additional equipment many more functions are available:

- a machine with a leg block helps to work the thighs, calves, buttocks or perform twisting exercises to pump up the abs;

- handrails - help with exercises to pump up the lower abs;

- the presence of racks with insurance allows you to work with a barbell without a partner’s insurance;

- A bench with parallel bars will allow you to do many more exercises.

- Adjustable bench equipped with an adjustable seat and backrest. The simulator also includes hinged stands, a spring bracket, a stopper, a clamp, and a limit chain. This exercise machine allows you to train not only with barbells, but also with dumbbells in a sitting position.

The features of this simulator include:

- the ability to perform bench presses at different inclinations, while adjusting the load, contributing to the comprehensive pumping of the body muscles;

- The installation of the exercise machine can be done not only in gyms, but also at home, especially if you choose a model that can be folded.

Buy or make it yourself

The question immediately arises of whether to buy or make a simulator with your own hands.

To answer this question, consider the advantages and disadvantages of one and the other option for purchasing a bench.

| Option for purchasing a bench | Advantages | Flaws |

| Buying a bench press | A wide range of simulators and their configurations. | ·High cost of goods. ·Inadequate quality. |

| Making a bench with your own hands | ·You can make a bench at your own discretion, taking into account all the features and wishes of its owner, and, most importantly, with high quality. ·To make a bench, you can use less expensive, but still high-quality materials. · Even taking into account the funds spent on purchasing materials for making the bench, the cost of the product will be significantly less than the store price. | Waste of time |

Based on the above, it becomes clear that the option of making a bench press with your own hands is still the leader, but taking into account the fact that not everyone has the opportunity and skills, it will still be easier to buy a machine. It all depends on the financial capabilities and preferences of the owner.

Criterias of choice

If you still decide to buy a bench press bench, you need to adhere to the following criteria:

- The practicality of the product, which is achieved by the quality of the material.

- No jamming when adjusting the elements of the simulator;

- Availability of hypoallergenic and water-repellent coating;

- If the machine is foldable, this will allow you to remove the bench after classes, thereby freeing up free space.

- If you don’t have a training partner, you need to choose a product with safety stops that ensure safe training without the possibility of the barbell falling onto your chest or causing other injuries.

These criteria are also relevant when making a bench with your own hands. To obtain a high-quality result, you must use only high-quality and durable material.

DIY bench press step by step

Making a bench press is a fairly simple process, but some skills in working with equipment and tools are still necessary:

- with a welding machine;

- with a grinder;

- drill;

- vice.

Having all the skills, you can start making the simulator.

Drawing

The first stage of manufacturing a simulator is drawing up its drawing, which will indicate all the features of the selected design and its dimensions.

To draw it up, you can take a sketch from the Internet or take measurements from a simulator located in the gym.

Preparing everything you need

According to the drawing, the working material is prepared:

- Profile pipe 40*40 mm and with large thickness of walls. For the manufacture of individual structural elements you will also need a steel strip 40 mm wide or a thick pipe.

- Roulette.

- Vise.

- Bulgarian.

- Drill.

- Welding machine.

Step-by-step guide to making a bench press frame

- 2 pieces of 830 mm each are cut from the pipe. These racks in the structure serve as the legs of the frame and support for the bar, so the material for their manufacture must have special strength. On the finished racks, a mark is made at a distance of 340 mm from the floor with a simple pencil.

- Next, a section of 520 mm is cut out to connect the racks (830 mm each). The connection will be made at the location of the marks made. When making welding seams, it must be taken into account that the load exerted on them will be large and with considerable fluctuations.

- A section is prepared that acts as a stand on the opposite side of the structure, measuring 340 mm.

- The next element is a bar connecting the front and rear pillars of the frame. Its size is 970 mm.

- To evenly distribute the load on the surface of the flooring, special extensions are attached under the legs. For the front legs, the extension sections are 220 mm, for the rear legs – 300 mm. The sections are fixed using a welding machine.

- Using prepared steel strips and a vice, the petals of the racks are bent, in the amount of 2 or 4 pieces. Outwardly, they should resemble the English letter “J”. The rear side should be 70 mm, and the front side should be approximately 20–30 mm.

- At the end, a pair of holes are made with a diameter of 1 cm. They serve for the entry of reinforcing rods. The holes should not be through, and there should be no rods coming out from the reverse side. They are located on the beam connecting the main posts, marking 16 cm from its center.

Instructions for making a lounger

To make a bench rest you will need:

- Steel sheets (2 mm).

- Door hinges.

- Ribless reinforcing rod.

- Thick foam rubber 20 mm.

- Sanded board.

- Durable and water-repellent fabric.

- Welding.

- Bulgarian.

- Knife.

- Roulette.

The work is done not only with metal, but also with wood.

- The first stage is the preparation of two steel sheets:

- first 350*160;

- the second is 350*940.

- The first sheet is fixed in the area where the legs are located, slightly protruding beyond the rack (5–10 mm), using welding.

- The second sheet is fixed using a door-type hinge, made by hand. Such a loop is welded with a weld, one side to the pipe, and the other to the sheet of the deck.

- On the back side of the plate, at a distance of 100 mm, ribless reinforced rods (2 pcs.), 300 mm in length, are fixed. They will allow you to raise the back of the lounger to perform different types of exercises.

- Next, a polished board is placed on the plate, the size of which should be 5 mm wider than the steel sheet. The boards are fixed to the steel sheets using self-tapping screws, from the bottom side, but so that the screws do not go right through the wood.

- Foam rubber 20 mm thick is laid on the board, having previously lubricated the board with glue, and everything is sewn up with rubberized fabric with excellent density. You can use a construction stapler to attach it.

Video on how to make a bench press with your own hands from metal profiles 40*40 mm:

You can read how to make a horizontal bar here.

To summarize, we can say that a bench press bench can be installed at home, either purchased in a store or made with your own hands.

To make a bench, you need skills in working with metal (subject to the manufacture of a metal frame) and the availability of high-quality and durable materials.

Depending on the selected model of the simulator, first of all, a drawing is created and only after that, you can begin to manufacture the product. If you follow the sequence of the technological process, the simulator will turn out no worse than a store-bought one and even better.

Source: https://guru-remonta.ru/obshhie-voprosy/sdelat-skamyu-dlya-zhima.html

Preparation of the drawing

The dimensions of the bench must meet individual requirements. To do this, you can use the standard parameters:

- the length of the supports is 97–122 cm;

- distance between racks - 52 cm;

- the height of the front part of the bench is 83 cm, the back part is 34 cm;

- the parameters of the stand for the rear supports are 30 cm, for the front ones – 22 cm.

The length of the adjustable design in the back reaches 16 cm, in the front - 94 cm. The inclined bench for bench press has other parameters: in the back - 36 cm, in the front - 114 cm. The width of the bench depends on the athlete’s build and the area of the room, in where the simulator will be located. On average, the dimensions reach 29–32 cm. Experts do not recommend using smaller sizes than standard ones, since this can negatively affect the activity of the muscular system, and therefore the result of the workout.

The distance from the floor to the bench should correspond to the parameters of the lower arm of the lever intended for the legs; an additional 10 cm is added. The length of the lounger is selected depending on the height of the athlete.

You can draw up drawings yourself or find ready-made ones in the public domain. The sketch should display all the design features of the future product and the dimensions of each element. If necessary, the initial parameters are changed in accordance with individual requirements. Athletes who go to the gym and work out on professional equipment will be able to take measurements and develop their own scheme based on them.

Types of wooden benches, their features, shapes and sizes

Compact dumbbell rack made of profile pipe

Sports equipment must be stored in such a way that it is convenient to use. Therefore, to store dumbbells and barbells at home, you can use a simple rack made of a profile pipe.

Factory racks are obscenely expensive, so it will be much cheaper to make a rack yourself. The frame is made of corrugated pipe, and the dumbbell mounts themselves can be made from pieces of steel plate.

The first step is to cut the blanks from the profile pipe and metal to size. Next they need to be polished on a grinder. Then the master begins welding.

Main stages of work

First you need to weld the base - this will require three sections of profile pipe. After this, two more sections of the profile will need to be welded vertically to the “jumper”. The segments must be the same length.

Please note that the pipes should be located at a slight angle relative to the horizontal plane. Next, mounts for dumbbells from pieces of metal plate are welded to the profiles at the required angle.

At the last stage of the work, all that remains is to weld the stops to the racks - for this, the master uses two studs and extended nuts. But you can also take smooth reinforcement of the required diameter.

Then you need to clean everything with a grinder with a blade disc and paint it. For details on how to make a dumbbell rack from a profile pipe, watch the video on our website.

What is

In appearance, the bench press bench resembles an ordinary bench. This equipment was specially created for strength sports. In terms of design and construction, this equipment can be produced in several versions. Often there are models with several adjustable parts, special horns that hold the barbell. Also popular are benches in which the level of backrest can be independently adjusted.

By and large, a power bench or, as it is also called, a bench press bench is a unique exercise machine that combines the functionality of several sports equipment. Thanks to the use of such equipment, you can perform various strength exercises, pump up your abs and train various muscle groups using a barbell or dumbbell.

When planning to create a bench with barbell racks with your own hands, it is important to decide for what purpose it will be used.

Dimensions

Device

Improved bench model

The bench can be improved - for example, by adding bars to it. This will provide an opportunity to additionally load the muscles of the chest and triceps.

Materials and tools

In order to install parallel bars onto an existing bench press, you don’t need a lot of tools.

The following materials are needed:

- bars;

- welding machine.

That's all. Installing beams is not as difficult as it seems at first glance.

Assembly work

It will take 20-30 minutes to weld the bars to the bench press.

Necessary:

- Get a welding machine and a special mask to protect your eyes.

- Weld the beams to the bench.

The improved bench model is ready. Now there is an opportunity to diversify your home workouts.

Material options for a homemade barbell

There are two simplest options for fretboard materials: iron or wood. It’s easy to decide on a wooden base for the bar, since you can use, for example, an old wooden rake. The advantage of this option is that the tree will not add extra weight to the bar if it is not necessary.

To turn a rake into a suitable form for a projectile, you need to remove its handle in any suitable way, the main thing is that only one stick remains from it, which will be used as a basis for pancakes. We’ll look at what else you can use to make a barbell and weight plates below.

Another option for the bar could be, for example, a metal rod if you are planning classes with a weight of more than 50 kilograms.

The length of the rod should be 2 meters, and the cross-sectional diameter should be 35 millimeters; these are the optimal requirements for comfortable playing sports. You can also use a metal pipe with a diameter of 4 centimeters, but it is not suitable for the heavy weight of the pancakes.

Making weight plates

Making pancakes for the bar is not difficult, since even ordinary plastic bottles are suitable for pancakes. These bottles need to be filled with something heavy, it can be cement, sand and stones, and even plain water. What the bottles will be filled with depends only on how much weight is needed, large or not.

You can use 1.5 liter bottles, as well as 2 liter bottles, it all depends on the desired weight. To make such pancakes, just fill them with the desired contents, and then put them on the ends of the bar and securely attach them with tape.

Video

This video shows you how to make an incline bench press.

Those who play sports at home and have the appropriate equipment at their disposal know how painful it can sometimes be to trip over them. To prevent this from happening again and to keep all the weights, weights and dumbbells organized, you need to have a rack. It can be purchased at a sports store, but it will be much more economical to make it yourself. How exactly, read the step-by-step instructions.

Materials

To make a dumbbell rack with your own hands, prepare:

- sheet of plywood 4.5 x 28 x 110 cm;

- rectangular bars 5 x 15 cm;

- self-tapping screws;

- screwdriver;

- saw;

- roulette

Step 1

. For the bottom rails of the rack, cut off two pieces one meter long from the timber.

Step 2

. For the legs of the stand you will need 4 pieces of timber 55 cm long.

Step 3

. Place two meter-long pieces of wood together and, stepping back 33 cm from each edge, make marks for attaching the transverse legs of the stand.

Step 4

. Between the long bars, place the prepared four parts of the beam of the same length. Place them perpendicularly, as shown in the photo. Align them and secure them with nails or self-tapping screws. After this, be sure to check the stability of the resulting structure and correct it if necessary.

Step 5

. Attach two small bars to the sides of the finished base of the stand. Bevel their upper corners for an aesthetic appearance.

Step 6

. Attach a sheet of plywood to the prepared base as a tabletop. It should be slightly longer than the base of the stand. The width is larger than dumbbells.

Step 7

. Attach the edges to the tabletop along the edges. Cut them out of bars in advance.

Step 8

. Secure long, low bars along the tabletop exactly in the middle. There will be two of them in total. When deciding on the height, proceed from the dimensions of the dumbbells. Longitudinal slats are needed to fix dumbbells on the tabletop.

Now all you have to do is sand all the surfaces of the resulting stand and, if desired, cover it with stain or varnish. In this case, no final processing was carried out.

You can place weights at the bottom of the rack and dumbbells at the top.

Many people want to have a beautiful body with defined muscles. Unfortunately, not everyone has the opportunity to visit a gym where special equipment is available. Exercises on homemade exercise equipment, such as a do-it-yourself bench press bench, will help keep your body in good shape - making one yourself is not at all difficult. It is designed to train different muscle groups, and even among professional athletes it is considered an effective sports equipment.

Bench benches are divided into two types: horizontal and adjustable. They differ both visually and functionally.

A horizontal bench press with four fixed supports is the simplest basic design. It only implies the user's supine position during training. Such sports equipment is low-functional and is mainly suitable for working the pectoral muscles, as well as the front deltoids.

In a three-post design, two posts are used to mount various equipment and barbell petals. Most often it is equipped with the following sports equipment:

- leg block – designed for performing exercises on the thighs, calves, buttocks, as well as crunches to work the abs;

- additional handrails – will allow you to effectively train your lower abs;

- retractable racks – make it possible to perform exercises with a barbell without additional insurance.

- parallel bars - for push-ups.

These and other devices significantly expand the functionality of the horizontal bench.

Another type of sports equipment for bench presses is an adjustable bench. In it, the lounger (back) can be adjusted in height. The package includes racks with various accessories: brackets, stoppers, clamps. Exercises on such a bench can be carried out both sitting and lying down, using equipment for dumbbells and barbells. With this machine you can perform bench presses at different angles, pumping up many muscle groups. This adjustable bench is most convenient for installation in an apartment and does not require the use of other exercise equipment, as it performs many functions.

A simple horizontal design is quite easy to make. However, if you want to independently supplement such a bench with the devices described above and an adjustable lounger, it will require much more effort and skill.

With three supports

Adjustable

Photo of a barbell with your own hands

Note!

Note!

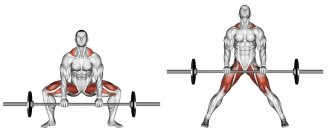

Squat racks are a necessary attribute for safe and comfortable barbell work in the gym or even at home!

Typically, the most commonly used device is the barbell squat. It will be enough to add a bench to the racks in order to get a full-fledged sports bench for performing bench presses, however, the supports in this case should have a small height so that it is convenient to remove the apparatus during the exercise.

In addition, the design can be used to perform the “military press” and other variations of the press in a standing or lying position. In general, racks can be called a universal training device, moreover, which you can make yourself.

Varieties

Do-it-yourself bench presses can be made in two versions:

- all-welded construction;

- dismountable with bolts.

Each of them has its own advantages and disadvantages.

An all-welded bench is a monoblock that is manufactured by welding parts. Its main advantages are stability and reliability, since the fastening method used will not allow the seams to come apart even under heavy loads. Such a horizontal design is bulky, its installation is impossible in small rooms, which is especially important in a small apartment. Its functionality is also low, since it does not allow the use of additional devices. This power bench is structurally simple, which makes it durable. It is not difficult to make it if you have the skills to work with a welding machine.

A collapsible transforming bench is the best installation option in the house. It is compact and does not take up much space. Its functionality is higher than that of a candy bar. If you add it with an adjustable backrest, you get an inclined bench. This will allow you to perform a variety of exercises on the muscle groups of the legs, arms, shoulders and buttocks, which provides a comprehensive development of the entire muscle mass of the human body. It can be installed and disassembled in a matter of minutes. Assembling a transformer requires skill in using various tools, such as an angle grinder, a drill and others. It is more difficult to manufacture than an all-welded model.

Dismountable with bolts

All-welded construction

About sizes

Here in Fig. The dimensions of 3-support exercise machines for people of average height are given. On the left is a fully functional one with a removable desk, hand and foot levers. The main materials are corrugated pipe 60x40x2 and round pipe 30x2; stop for lifting the board – pipe 20x2. The board is 16 mm plywood with sheathing, as described below.

On the right is a simple compact one. The height of the bench above the floor is selected individually, measuring from the heel firmly planted on the floor to the inner bend of the knee joint. Basic materials as in the previous case; The adjustable rear leg allows you to transform the apparatus for seated exercises. But remember: the barbell from this simulator should only be lifted from the approach!

Special benches

A special type of sports equipment is benches for hyperextensive exercises. Their goal is to achieve leanness and flexibility without gaining excessive muscle mass. In fact, hyperextension can be done on a large ball, or just on a mat, but the best results are obtained on a special bench.

Benches for hyperextension, due to anatomical and physiological differences, are available for men and women, see fig. A strong Amazon can do hyperextension exercises on a men’s bench, but ladies whose goal is to get rid of riding breeches, have a slender posture and a flat stomach only need a women’s bench for hyperextension, on the left side of the trail. rice. To start getting yourself in order without risking your reproductive health, it’s still better to sit on an inclined bench with a curved board, or do press exercises with a weight, also sitting on a special bench, on the right.

Note:

drawings of a bench for hyperextension with height adjustment are given in Fig. Materials – profile pipe 40x25x2, 35x15x1.5 and round 25x1.5; desk made of plywood 12-14 mm. For desk lining, see below.